AESPL offers engineering support for several types of boilers for your thermal power plants, waste or sewage sludge incineration plants, refineries, petrochemical industries and process plants. AESPL advises on the appropriate technology and support you in the conceptual phase as well as during execution stage.

In close cooperation with customers, we can work on projects considering various standards such as IBR, ASME, EN and others.

Basic and Performance Engineering is a core area with a lot of significance that decides the initial steps of the entire power plant design. It involves the complete sizing of the power plant equipment, ensures adequacy of the system considering several variables, and maximizes the reliability of the unit under steady state and transient conditions, checks safety of the plant, confirms easy operation of the plant with reduced maintenance and provides the necessary design redundancy to achieve the maximum plant availability.

Detailed Engineering is an essential service in AESPL that ensures the proper conversion of the ideas generated in the Basic and Performance Engineering stage into an Executable version strictly within the norms and standards stipulated by the respective regulations that are in vogue in the countries where the products get manufactured and installed.

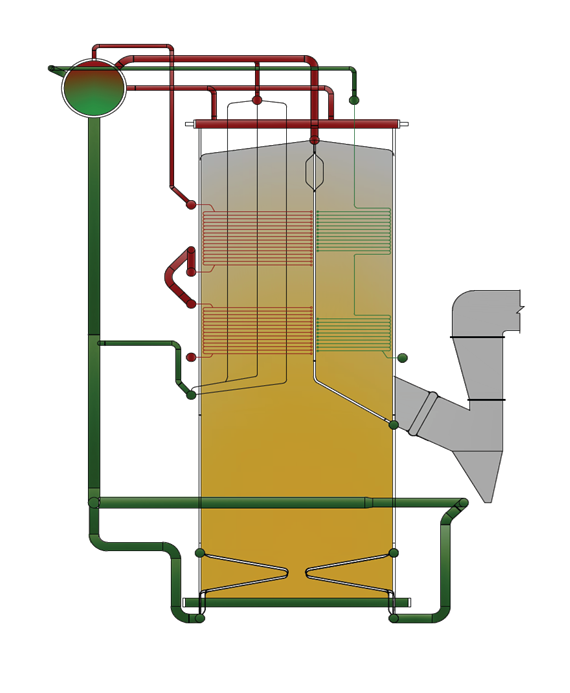

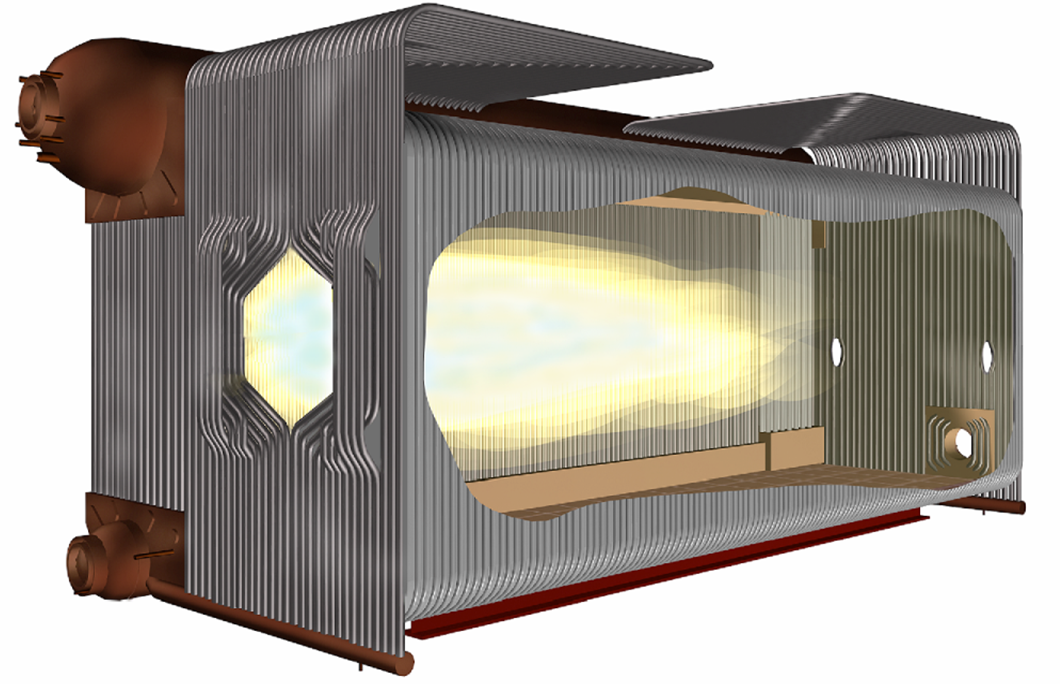

Atmospheric Bubbling Fluidized Bed (BFB) Combustion Boilers or FBC is a time tested combustion technology to burn low grade fuels in a most efficient way.

The fuels include different coals, high volatile lignites and all bio-fuels such as rice husk, ground nut husk, coffee husk, ground nut shell etc.,

AESPL does not have any limitation on the capacity of the fluidized bed boiler, the steam parameters, or the fuel range that are to be covered in the design of the plant. AESPL offer boilers with and without in-bed tubes depending on fuel characteristics and customer needs.

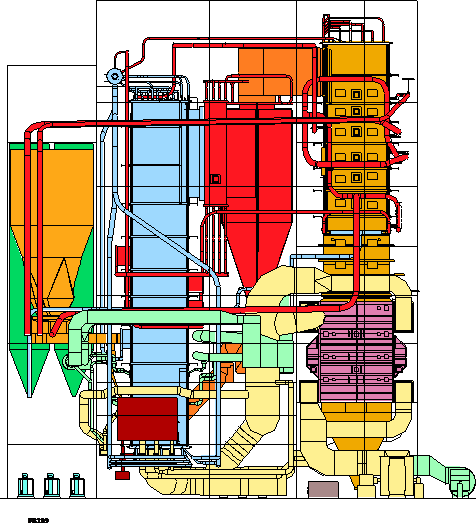

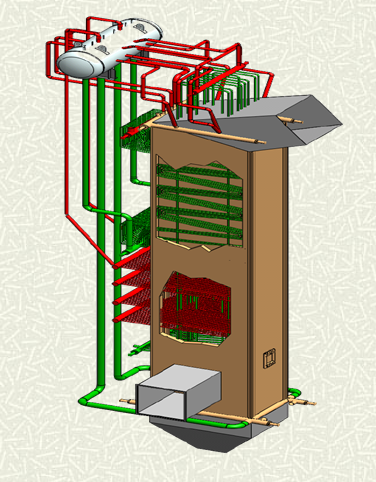

Atmospheric Circulating Fludized bed Combustion (CFB) is a well proven combustion technology to burn low grade fuels and hard to burn fuels in a most efficient and environmental friendly way.

AESPL offered CFB boilers can accommodate a wide range of fuels like coal, coal washery rejects, high volatile lignites and low volatile petroleum cokes, all industrial wastes like char, car tires, leco fines etc., The list also includes all bio-fuels such as rice husk, bark, ground nut husk, coffee husk, ground nut shell etc.,

AESPL does not have any limitation on the capacity of the fluidized bed boiler, the steam parameters, or the fuel range that are to be covered in the design of the plant. Our CFB design is unique with less in-furnace heat exchangers, less refractory, lesser auxiliary equipment and thus with reduced maintenance needs. With our CFBs the clients can enjoy a lower CAPEX and OPEX.

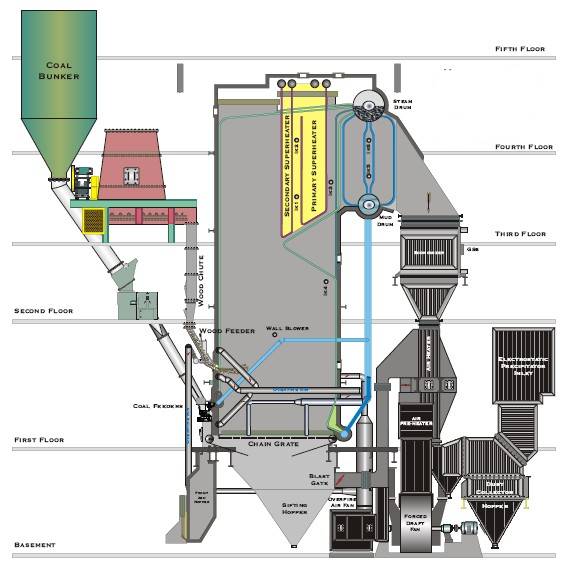

Traveling grates are the usual combustion modes of burning bagasse – the waste from Sugar Plants- as a fuel. AESPL can design and supply traveling grates suitable for burning bagasse and other bio fuels along with coal for steaming capacities up to 200 tonnes per hour with pressure and superheat temperatures up to 150 bar and 540⁰ C. AESPL can also supply pulsating grate designs for burning Palm Industry wastes.

AESPL has the expertise to design and supply oil and gas fired water tube boilers, of several types such as packaged, D-type or utility size, independently for industrial, petrochemical and refinery applications or as auxiliary boilers for utility applications. The steaming capacity and parameters are presently up to 350 tonnes per hour at 150 bar and 540⁰ C.

Most industrial applications have waste gas at high temperatures that are let into the atmosphere through the stack. The Sponge Iron Plants, Cement Plants, small power plants with diesel generators are some examples. AESPL can provide suitable waste heat recovery systems to recover the heat from these waste gases and generate steam either for process use or for power generation, and thus offer a very cost competitive energy solution.

A Heat exchanger is important from the view point of energy conservation, conversion and recovery. Its importance is also increasing from the standpoint of environmental concerns. Many industries such as Process, Power, Transportation, Air-conditioning & Refrigeration, Cryogenic, Heat Recovery and Alternate Fuels etc., use heat exchangers. A variety of heat exchangers are used in these industries and in their products. These heat exchangers are into many classification according to the heat transfer processes, number of fluids, constructional features, degree of surface compactness, flow arrangements, and heat transfer mechanisms etc.,

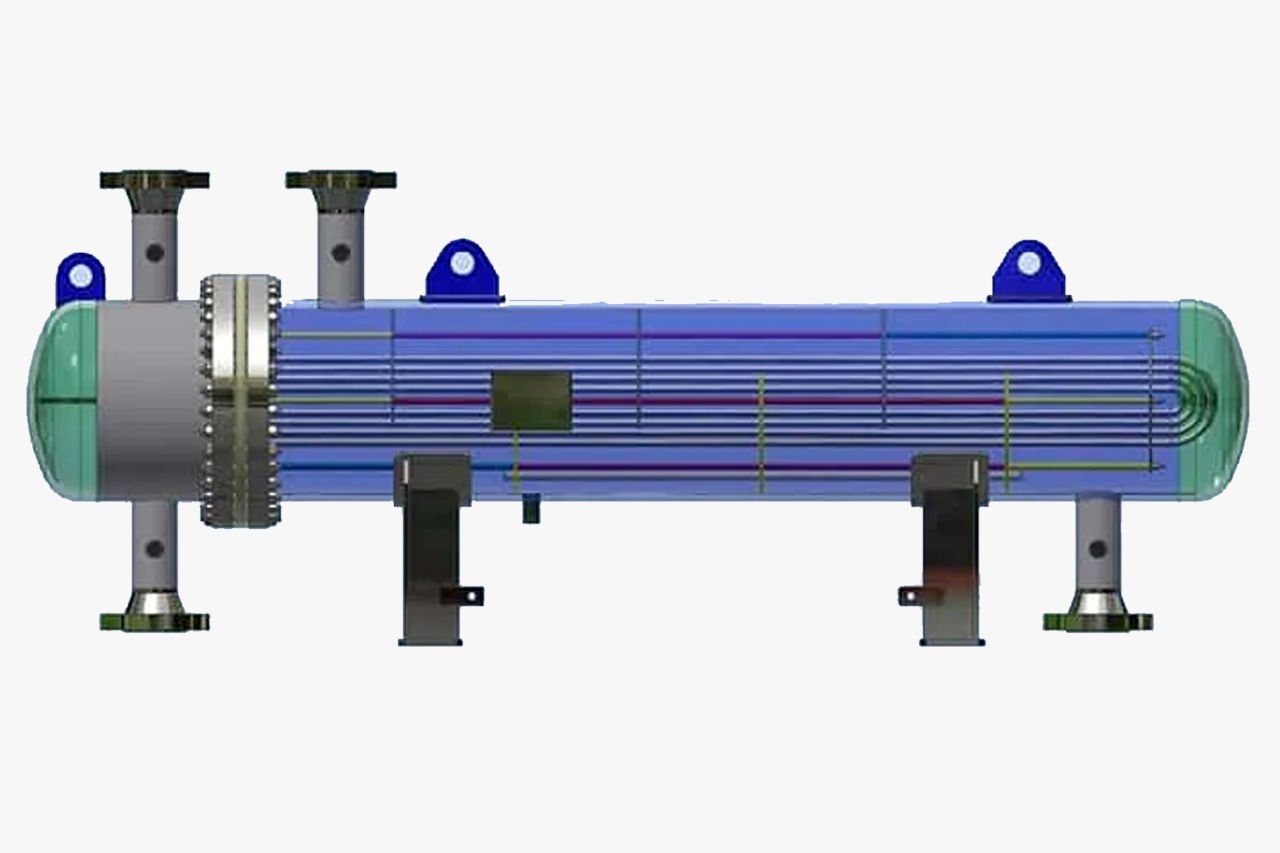

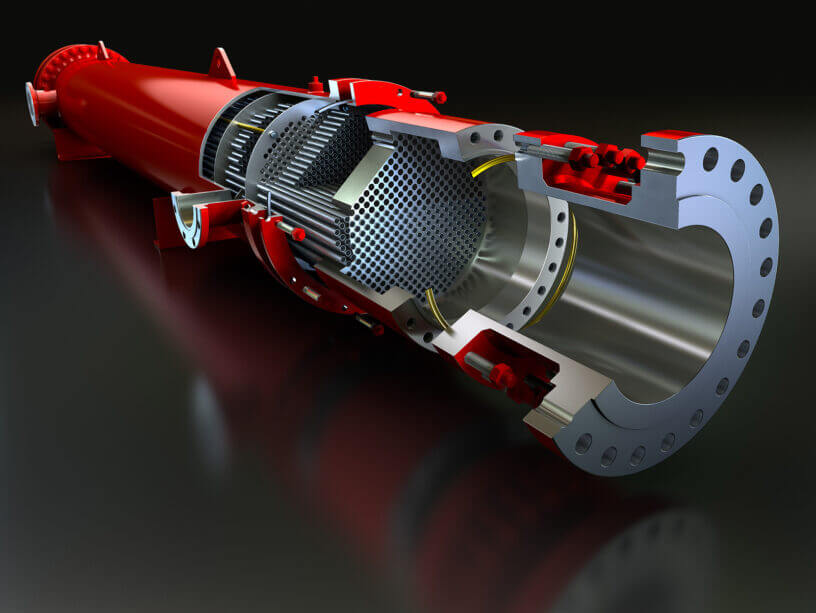

AESPL can support you with the design and supply of their Shell & Tube Heat Exchangers which are the work-horses of the process industries. AESPL heat exchangers usually consist of heat exchanging elements such as a core or matrix containing the heat transfer surfaces, and fluid distribution elements such as headers, inlet and outlet nozzles and pipes etc., There are no moving parts in our heat exchangers – usually. There is virtually no limit on the operating pressure and temperature.

| Materials | Carbon Steel Stainless Steels Hastelloy® Inconel® Incoloy® Duplex Alloys (2205, 2207) Copper and Copper Alloys Super Austenitic Stainless Steels |

| Rated Pressure | 3000 PSIG to Full Vacuum |

| Temperature Rating | 1,200 to -325 ºF |

| Applications | Condensors Evaporators Glycol-to-glycol exchangers Heaters Interchangers Product coolers Reactors |

| Services | Sandblasting Painting Passivation Post-Weld Heat Treatment Radiography Helium Testing |

| Compliances | API 660 ASME code TEMA standards |

| Quality Assurance | Leak Testing Pressure Testing QC Stamps on all welded/processed material Liquid Penetrant Testing Magnetic Particle Testing Certified Welding Inspection Certified Radiographic Interpretation Multiple Integrity Tests Performed On All Exchangers |