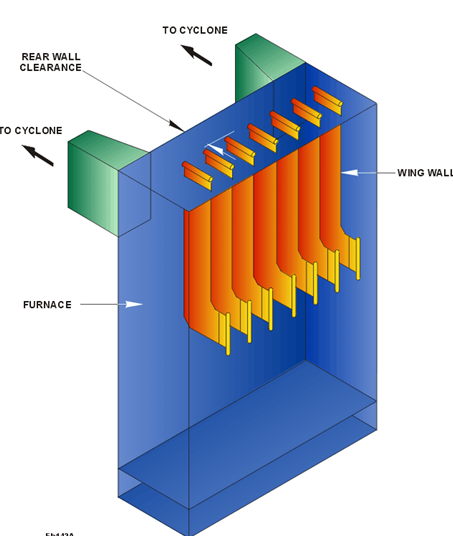

AESPL can undertake either in-kind replacement or newly designed replacement of pressure parts of the existing boilers. AESPL specializes in the design and our manufacturing partner specializes in the boiler pressure parts such as furnace wall panels, superheaters, economizers and cyclone panels from the manufacturing facility. AESPL can deliver ex-works or to a nearest port to the customer’s plant or to the customer’s site itself.

Fabrication facilities are IBR certified. State of the art equipment for pressure part fabrication such as plate, tube and panel bending equipment, automatic, semi-automatic and manual welding equipment, fin welding machines, swaging facility, heat treatment furnaces etc.,

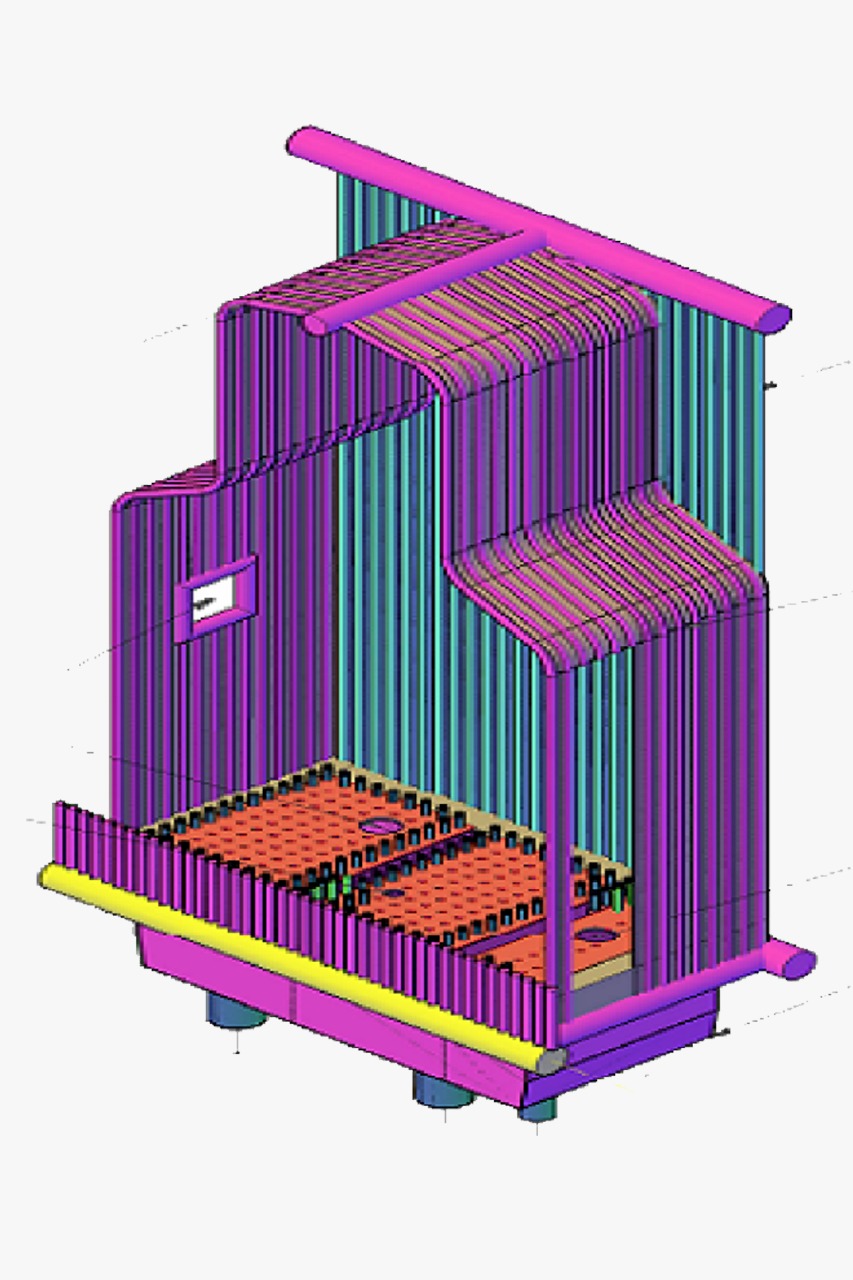

AESPL takes the overall responsibility of Design, Engineering, Procurement, Assembly and Testing of the following skids:

AESPL skid designs are made such that the skids are engineered and fabricated in different skid mounted parts for the ease of transportation and installations at site. The skids are compact and integrated, and Ideally suited for quick installation and short-term operating environments, saving start-up time and space.

The Fuel Gas Skid removes contaminants and liquids from the natural gas stream and pressure regulates it to prepare for use as fuel.

Chemical dosing skids are used to inject chemicals in the process where injection in specific quantities is necessary. AESPL chemical dosing skids solutions are used to dose the pre-set quantity of chemical into the steam drums or process pipeline as per desired proportion based on the plant’s need.

Chemical storage tanks are mounted on the skid to store the chemical to be dosed. Positive Displacement (PD) pump as per API 675 are used to feed the chemicals.

Common Skid Components Include:

All skid packages are fully factory tested and passed through our Quality Assurance process before shipment.

Advantages of using AESPL

The bottom ash of fluidized bed boilers contains large amounts of physical heat. When low quality coals are used in these types of boilers, the bottom ash quantity is normally more than 40 % and the physical heat loss is approximately 3 % if the bottom ash is discharged without cooling. Bottom ash cooler (BAC) is often used to treat the high temperature bottom ash to reclaim heat, and to facilitate the easily handling and transportation of ash. The high temperature bottom ash at around 900-950 C from fluidized bed boilers need to be cooled to around 200-250 C for handling and conveying to the ash silos located far away from the boilers in the power plant.

AESPL can support you with two designs – Fluidized Bed Ash Coolers (FBAC) and Rotary Bed Ash Coolers (RBAC) depending on your needs.

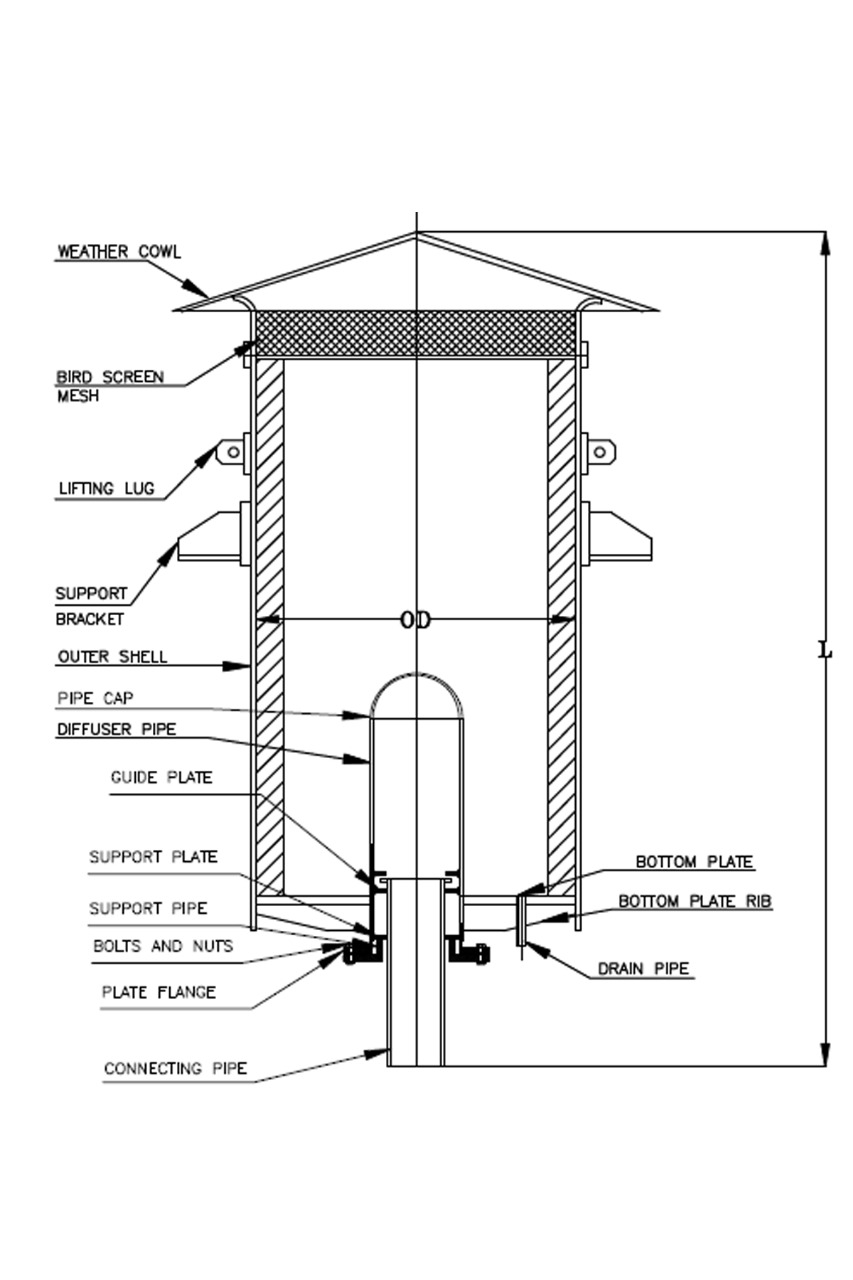

A vent silencer is a device that is intended to reduce the noise levels created when high-pressure gas or steam is expanded to the atmosphere. This noise is produced by the rapid turbulence of the mixing gas jet and energy release of the compressed gas. Most of the noise occurs at the expansion across the valve and is emitted at the stack opening. The silencer is installed at the exit to muffle this noise.

AESPL can supply the steel structural and air and gas ducting according to OEM’s designs for all boiler related jobs or for other industries and refineries. EPC contractors for Waste to Energy plants seek such support wherein they need manufacturing to be done as per their boiler design. Similar requirements from Steel designers for fabricating support of their structural steel components can be met with AESPL facilities and their project coordination.